Reduce Expenses with Preventive strapping machine repair Programs

Wiki Article

Top Tips for Effective Strapping Machine Repair and Maintenance Practices

Efficient strapping machine repair and maintenance is important for operational effectiveness in any type of product packaging environment. By understanding the machine's parts and implementing a structured maintenance timetable, companies can considerably lower downtime. Routine inspections and proper operator training better boost performance. Numerous neglect essential techniques that can prolong equipment long life. Discovering these techniques can disclose indispensable insights for improving maintenance methods and making certain excellent machine performance.Understand Your Strapping Machine's Components

In enhancement to these key parts, the control board enables drivers to establish parameters and keep track of the machine's efficiency. Understanding these elements is crucial for any person associated with the maintenance and repair of strapping machines, as it allows them to diagnose problems successfully and implement appropriate options. Understanding of each part boosts the overall durability and reliability of the equipment.

Establish a Normal Maintenance Set Up

Establishing a routine maintenance routine is vital for ensuring the ideal performance and durability of strapping devices. This aggressive technique allows drivers to anticipate potential issues prior to they rise into substantial troubles. A well-structured schedule ought to describe specific tasks, such as cleansing, part, and lubrication replacements, in addition to regularity periods for each and every task.By adhering to this routine, firms can decrease downtime and boost efficiency. It is a good idea to document maintenance activities to track compliance and recognize patterns that might show underlying issues. Including experienced employees in the maintenance procedure guarantees that jobs are completed correctly and successfully.

Integrating a list can promote comprehensive evaluations and ensure no vital components are ignored. Overall, a normal maintenance timetable not just maintains the capability of strapping devices but likewise adds to a much safer working setting, inevitably leading to minimized functional costs and boosted performance.

Conduct Routine Inspections

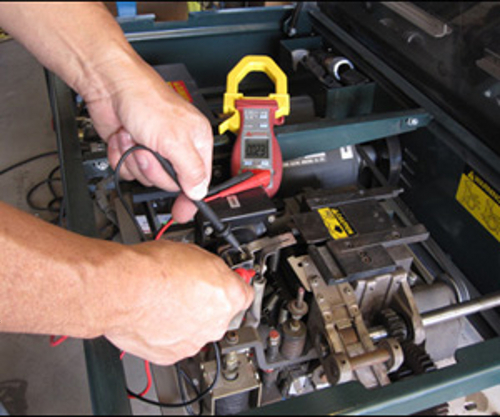

Conducting routine inspections is vital for maintaining the performance of strapping devices. This process includes doing visual devices checks to determine any type of visible wear or damages, as well as regular performance testing to assure peak procedure. By focusing on these examinations, operators can avoid prospective concerns and prolong the life expectancy of the devices.Visual Tools Examine

Routine examinations play a crucial duty in maintaining the efficiency and long life of strapping makers. Performing a visual equipment check permits operators to determine visible wear, damages, or imbalance that may jeopardize efficiency. This examination ought to include analyzing vital elements such as straps, rollers, and seals for any indications of fraying, fractures, or rust. Furthermore, inspecting for loosened connections and making sure that all security guards remain in area is vital. Inspecting the machine's total cleanliness can likewise stop debris from impacting operation. Operators should record any kind of searchings for during these visual checks, as this details can assist future maintenance actions and aid in scheduling repair work without delay. Constant visual examinations contribute greatly to stop significant malfunctions and making sure smooth procedure.Normal Efficiency Testing

Regular efficiency screening is crucial for ensuring that strapping devices operate at peak performance. This practice includes carrying out regular examinations to examine the machine's capability and recognize any type of potential concerns prior to they rise. Specialists need to analyze vital parts such as tensioning, sealing, and alignment mechanisms, guaranteeing that each part performs according to maker specifications. Tracking cycle times and output high quality additionally offers important insights right into operational efficiency. By implementing a regular testing schedule, maintenance teams can cultivate positive analytic, minimize downtime, and extend the life-span of the equipment. In addition, recording test results permits for trend analysis, aiding to pinpoint repeating problems and maximize repair approaches. Eventually, regular efficiency screening is a basic element of effective strapping machine maintenance.Usage Top Quality Strapping Product

Utilizing top quality strapping product is necessary for making sure the efficiency and longevity of strapping equipments. The choice of strapping material straight impacts the performance of the machine and the stability of the bundles being secured. Poor-quality products can result in regular machine breakdowns, raised downtime, and the threat of product damage throughout transportation. It is suggested to select strapping materials that work with the particular type of strapping machine being made use of, as this can boost both performance and security.Additionally, high-quality strapping products are commonly designed to hold up against numerous ecological problems, such as temperature changes and moisture, which assists preserve the dependability of the strapping process. Purchasing premium materials not only decreases the regularity of fixings and maintenance but additionally promotes an extra reliable operation overall. For that reason, choosing high quality strapping material is an essential practice for effective strapping machine maintenance.

Maintain the Machine Clean

Maintaining a tidy strapping machine is important for peak efficiency and durability (strapping machine repair). Debris, dust, and dust can gather gradually, causing mechanical failures and decreased efficiency. Normal cleansing avoids the accumulation of contaminants that could interfere with the machine's procedureOperators should establish a constant cleansing schedule, concentrating on vital locations such as the feed system, belts, and rollers. Making use of suitable cleaner and tools made for the machine's materials is essential to avoid damages.

Furthermore, inspecting the machine for any signs of wear or deposit buildup throughout cleaning can assist identify possible problems early. Keeping the strapping machine clean not just enhances its performance however also cultivates a more secure working atmosphere.

Address Minor Service Quickly

Attending to minor repair work immediately is necessary for maintaining the efficiency of strapping devices. Identifying usual problems very early and organizing regular evaluations can protect against extra considerable troubles down the line. Additionally, utilizing high quality substitute components guarantees that repair services boost the machine's longevity and performance.Identify Common Issues

While strapping equipments are designed for longevity, they can still encounter usual concerns that, if left unaddressed, may cause more significant troubles. Operators needs to be watchful in recognizing these problems at an early stage. Frequent problems include imbalance of bands, irregular stress, and malfunctioning sealing systems. These concerns can cause below average strapping quality and enhanced downtime. In addition, deterioration on elements such as rollers and belts can cause operational inefficiencies (strapping machine repair). Routine monitoring of machine efficiency enables punctual discovery of these problems. Attending to minor repair work quickly not just boosts the machine's long life however likewise assures optimal performance, minimizing the risk of pricey breakdowns and production hold-ups. Prompt interest to these common concerns is crucial for reliable maintenanceSchedule Routine Assessments

Regular inspections of strapping devices are necessary for guaranteeing suitable performance and long life. By setting up these evaluations, operators can determine small issues prior to they rise right into significant issues. This proactive technique enables timely treatments, look these up minimizing downtime and expensive fixings. Assessments need to concentrate on elements such as belts, sensors, and motors, guaranteeing they are working correctly. In addition, operators need to check for wear and tear on parts that may need instant interest. Addressing small repairs immediately not just improves the machine's performance but additionally expands its operational life-span. Developing a consistent inspection regular fosters a society of preventive maintenance, ultimately resulting in boosted performance and minimized operational disruptions in the lengthy run.Usage High Quality Replacement Parts

Train Your Operators

Educating operators efficiently is crucial for the ideal performance of strapping machines. Well-trained drivers can identify the machine's limitations and functions, making sure maximum usage and minimizing review the threat of malfunctions. Comprehensive training must consist of comprehending operational procedures, safety methods, and fundamental troubleshooting strategies.Routine training sessions can enhance ideal methods and keep operators educated regarding any updates or changes in equipment. In addition, hands-on training enables drivers to obtain useful experience, which improves their confidence and competency.

Employing a mentorship program can further improve driver abilities, as skilled employees can offer real-time support and comments.

Involving operators in regular maintenance conversations fosters a sense of ownership, motivating them to take proactive steps in machine maintenance. On the whole, buying driver training not only improves machine effectiveness yet additionally leads to a safer working environment.

Paper Maintenance and Repairs

Proper documents of repair and maintenance is important for effective strapping machine procedure. Keeping a substantial maintenance log, tracking repair background, and organizing service documents can greatly boost machine longevity and performance. These methods assure that drivers have access to crucial details, advertising informed prompt and decision-making interventions.Maintenance Log Relevance

Keeping a comprehensive maintenance log is vital for guaranteeing the long life and performance of strapping machines. This log functions as a thorough record of all safety nets, fixings, and evaluations carried out. By documenting maintenance activities, operators can determine reoccuring concerns, consequently helping with prompt interventions prior to minor issues intensify into significant failings. A well-maintained log likewise aids in compliance with market regulations and requirements, supplying evidence of adherence to safety procedures. In enhancement, it permits much better scheduling of maintenance jobs, optimizing machine uptime and performance. On a regular basis reviewing the log can likewise assist in training brand-new workers, guaranteeing they comprehend the significance of constant maintenance practices. Eventually, a reliable maintenance log is an important device for improving operational integrity and performance.Repair Background Tracking

Efficient repair background tracking is important for the very best efficiency of strapping machines. By diligently recording every repair, drivers can determine repeating issues and evaluate the overall integrity of machine components. This methodical technique assurances that professionals have accessibility to important view publisher site info, such as the nature of previous repair services, components replaced, and any kind of alterations made. In addition, an extensive repair background permits for educated decision-making relating to future maintenance techniques and budgeting for spare parts. It likewise assists in abiding by industry criteria and laws that may require documentation of tools background. Eventually, constant monitoring of fixings not only improves machine durability however likewise maximizes functional effectiveness in the facility.Scheduled Solution Records

Consistently documenting scheduled solution documents is important for making sure the longevity and efficiency of strapping makers. These records supply a detailed overview of maintenance activities, permitting operators to track the frequency and nature of solutions performed. By keeping accurate logs, organizations can recognize patterns that might show potential problems, facilitating proactive repair services prior to considerable failings take place. Scheduled solution records likewise aid in conformity with guarantee demands and can boost resale value by demonstrating a commitment to maintenance. On top of that, they serve as a valuable source for specialists during troubleshooting, supplying understandings into the machine's functional history. Inevitably, constant documentation aids enhance performance and lessens downtime, adding to overall functional efficiency.Invest in Expert Servicing

Purchasing expert servicing for strapping makers is vital for guaranteeing their durability and optimal efficiency. Regular maintenance conducted by skilled professionals aids identify prospective concerns prior to they rise into pricey fixings. Specialists possess the knowledge to conduct comprehensive evaluations, adjust parts, and change used components utilizing premium materials.On top of that, specialist maintenance commonly consists of cleansing and lubrication, which are essential for maintaining the machine's effectiveness. This positive approach not only lowers downtime however additionally boosts the general efficiency of the strapping procedures. In addition, properly maintained tools commonly has a much longer lifespan, producing much better rois.

Stay Informed on Industry Ideal Practices

Remaining notified on industry finest techniques is crucial for drivers and maintenance groups liable for strapping machines. Consistently upgraded expertise helps ensure the reliable procedure and durability of devices. Experts should engage with sector magazines, participate in workshops, and participate in online discussion forums dedicated to strapping innovation. By doing so, they can learn concerning the most up to date developments, maintenance methods, and repairing strategies.Networking with peers can give understandings right into innovative remedies and typical challenges. Organizations might also take advantage of subscribing to newsletters or joining associations that concentrate on product packaging and strapping innovations. Engaging with manufacturers for updates on machine specifications and maintenance referrals is similarly essential.

Incorporating this expertise right into everyday procedures not just boosts machine efficiency however additionally decreases downtime and expensive repair work. Ultimately, remaining notified empowers teams to implement ideal methods that add to a more secure and much more reliable workplace.

Regularly Asked Questions

How Usually Should I Change My Strapping Machine's Parts?

Components of a strapping machine should be changed based upon use and wear. Typically, assessments every 6 months can direct needed replacements, guaranteeing perfect performance and preventing unanticipated failures that might prevent efficiency. Regular monitoring is important.What Are the Indications of a Malfunctioning Strapping Machine?

A defective strapping machine might display indicators such as irregular strapping tension, regular jams, unusual noises, error messages, or noticeable wear on elements. Timely identification of these problems can prevent more damage and maintain functional effectiveness.Can I Use Any Type Of Sort Of Strapping Product?

Not all strapping products are suitable for every machine. Particular equipments require assigned products, such as polypropylene or polyester, to guarantee peak performance. Making use of the incorrect kind might bring about inadequacy and possible damage.Exactly how Do I Effectively Clean My Strapping Machine?

To correctly clean a strapping machine, one must separate power, get rid of particles, and use a soft towel with a mild detergent. Routine maintenance assurances peak efficiency and extends the machine's life-span, stopping breakdowns.What Should I Do if My Machine Is Still Under Service warranty?

The proprietor needs to get in touch with the supplier or accredited dealership for support if the machine is still under warranty. They can provide assistance on repair services, prospective service choices, and warranty that warranty problems are kept.Recognizing these elements is critical for anybody included in the maintenance and repair of strapping equipments, as it allows them to detect concerns efficiently and apply ideal solutions. Establishing a routine maintenance routine is necessary for assuring the excellent efficiency and longevity of strapping makers. Utilizing high-grade strapping material is crucial for making sure the effectiveness and longevity of strapping devices - strapping machine repair. Keeping a comprehensive maintenance log is crucial for making certain the durability and effectiveness of strapping makers. Efficient repair history tracking is essential for the best performance of strapping makers

Report this wiki page